BSP stands for ‘British Standard Pipe’ threads. BSP is the most popular thread style in the United Kingdom and is very common in the UK commonwealth countries. They are also widely used for many applications in Europe and Asia. BSP male fittings have a conical 30-degree seat that mates against matching conical 30-degree female fitting or port. BSP fittings have a thread angle of 55 degrees and come in two thread types:

- BSPP — parallel threads, sealed with a bonded washer or O-ring, seated under the shoulder of the male fitting and the face of the female fitting or port.

- BSPT — tapered threads, sealed by a metal-to-metal wedge of the threads and the application of a thread sealant prior to installation.

Make sure to avoid the common mistake of confusing a BSP thread of 55 degrees with an American NPT (National Pipe Taper) of a 60-degree angle. BSP have rounded peaks and valleys, while NPT have flattened peaks and valleys. They may seem to fit, but the difference in thread angle and style will allow for leaking down the threads. When in doubt, verify the style with a thread gauge.

To measure a BSP and BSPP fitting, first determine the thread size:

- Measure the thread's OD (outside diameter) in inches.

- Subtract 25% from the OD measurement. i.e., if the OD of a BSP male thread measures 2” the thread size will be 1 ½”.

- Next, count the number of threads per inch over a short length and multiply by 4. For example, if you count 2.75 thread crests over 1/4” the calculation will be:

2.75 X 4 = 11 threads per inch - Therefore, in this example, if the OD of a BSP thread is 2”, the thread size will be 1 ½” with 11 threads per inch.

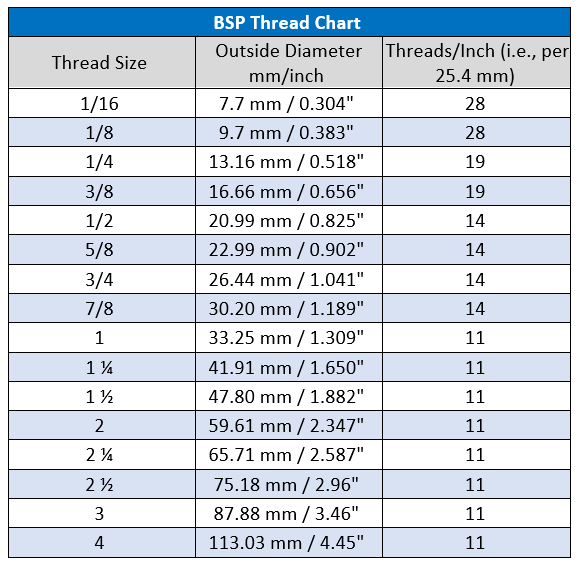

- Use this measurement to cross-reference the thread size you’ve measured to the chart below, also showing threads per inch (TPI).

Measuring BSPT fittings

Because BSPT fittings are tapered, the process for measuring them is different from that of BSPP. The BSPT outer diameter varies on the taper, so the above formula is not as accurate. Instead of beginning by measuring the outer diameter, first determine the fitting’s inner diameter by taking a calliper reading from inside its bore. Once determining the ID of the bore, reference the table to find the external thread dimensions.

Since you seemed interested in our instrumentation content, check our free BluePrint as a helpful resource: